Following the order of one of our customers specialized in food supplements, we proceeded to the complete reconditioning of a used NOACK blister machine – year 1992.

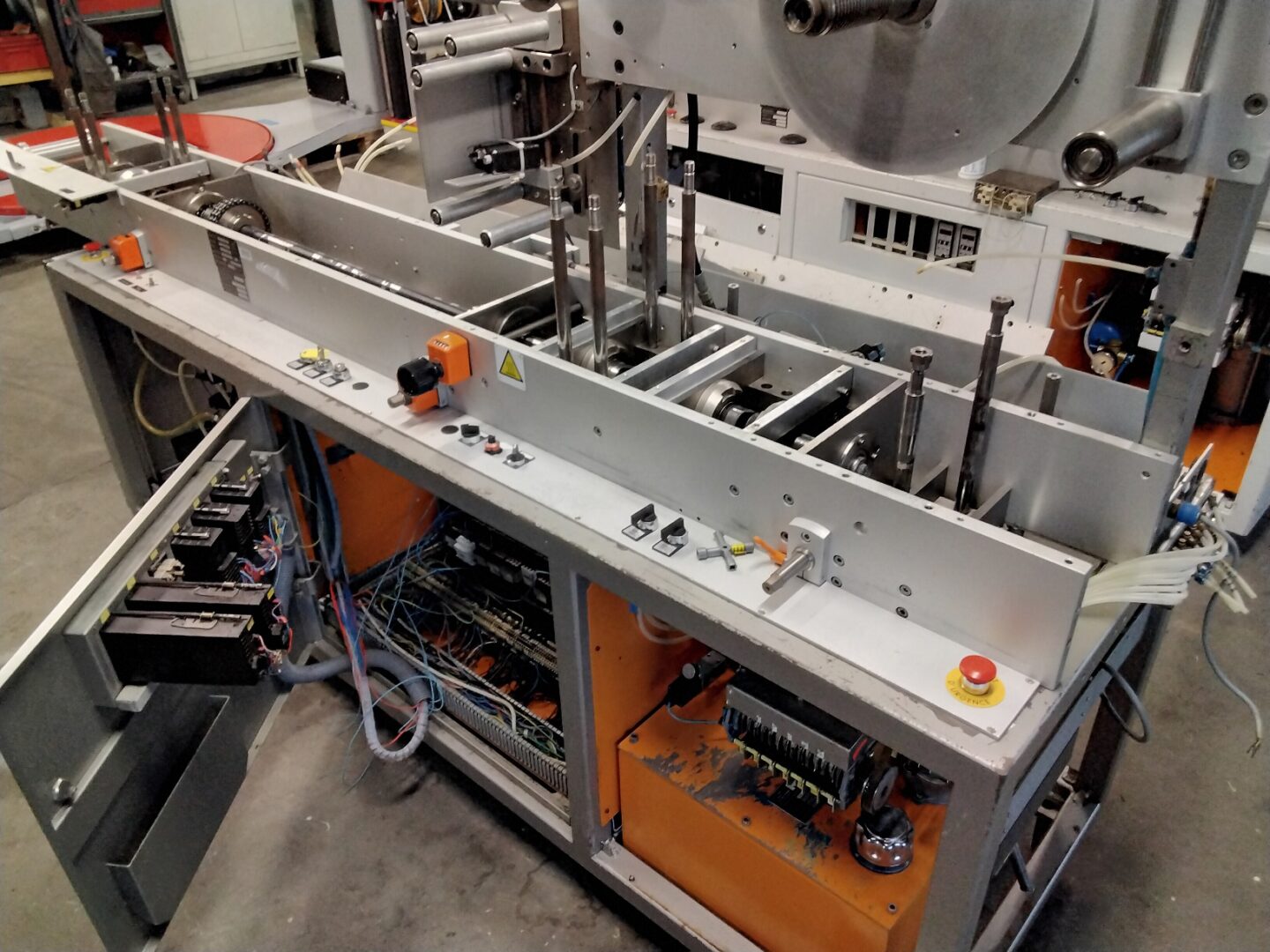

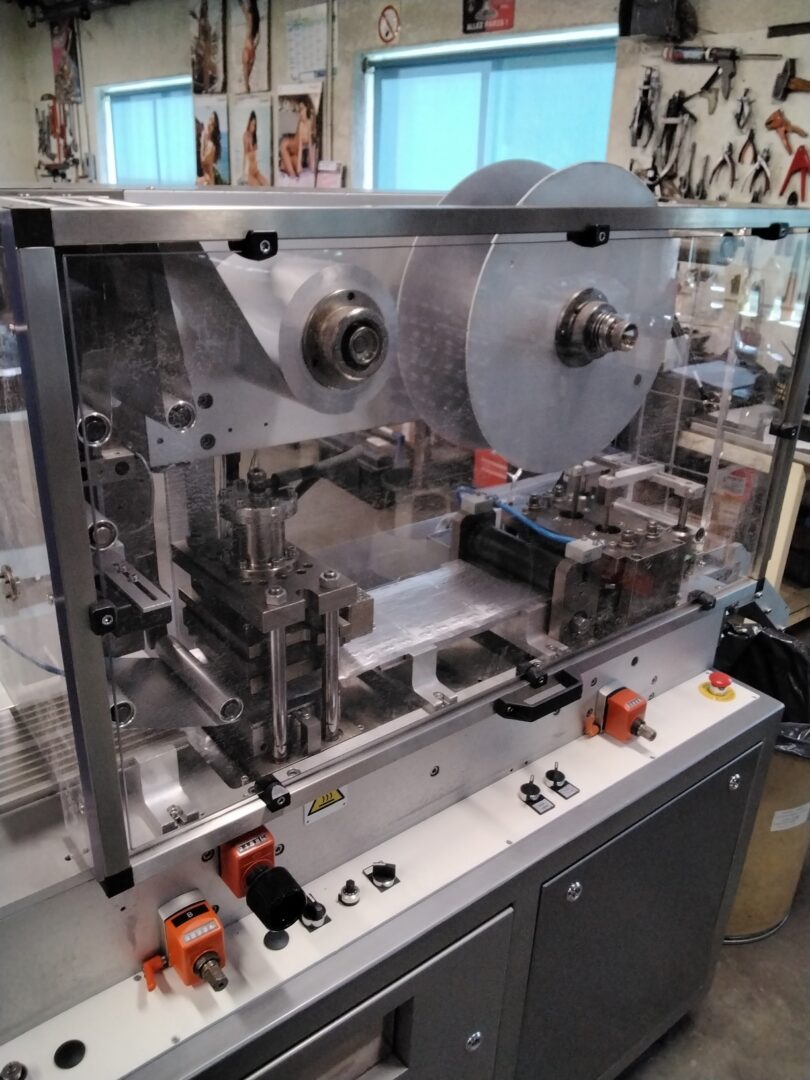

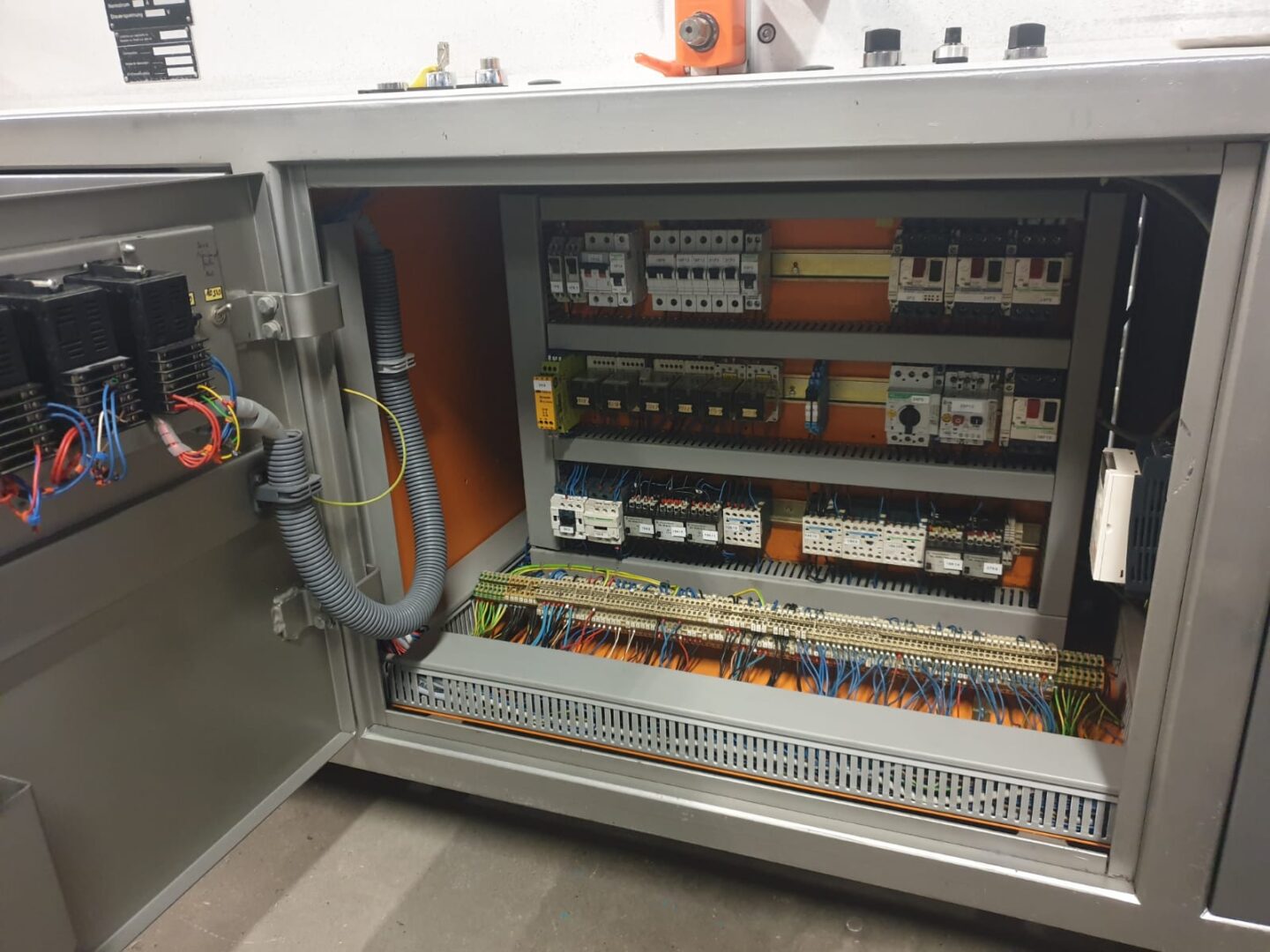

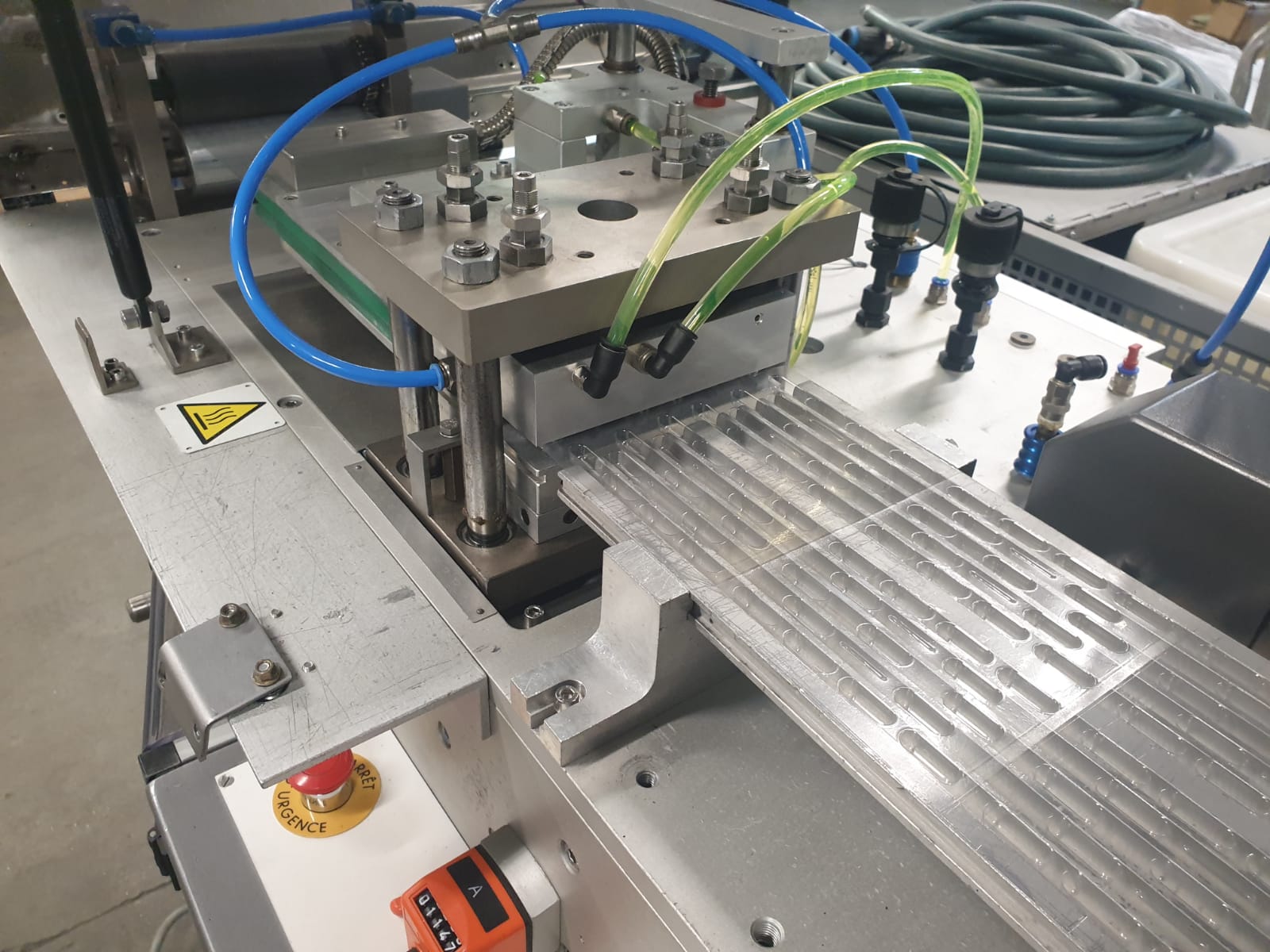

The following work was carried out in our workshop:

- complete mechanical overhaul

- change of safety guards

- complete painting

- installation of a new format

- rewiring and replacement of temperature probes

- change screen and PLC box

This operation lasted one month.

In reconditioning / repair:

After reconditioning:

Below is the link of a video showing the tests carried out in our workshops with the customer’s product: